PCBs are manufactured in highly advanced factories. The manufacturers try to eliminate all risks of defects going unnoticed. A variety of PCB inspection methods are used to ensure there are no defects in the final PCBs. The boards undergo several steps during the manufacturing process and are checked after each important step.

Manual Visual Inspection

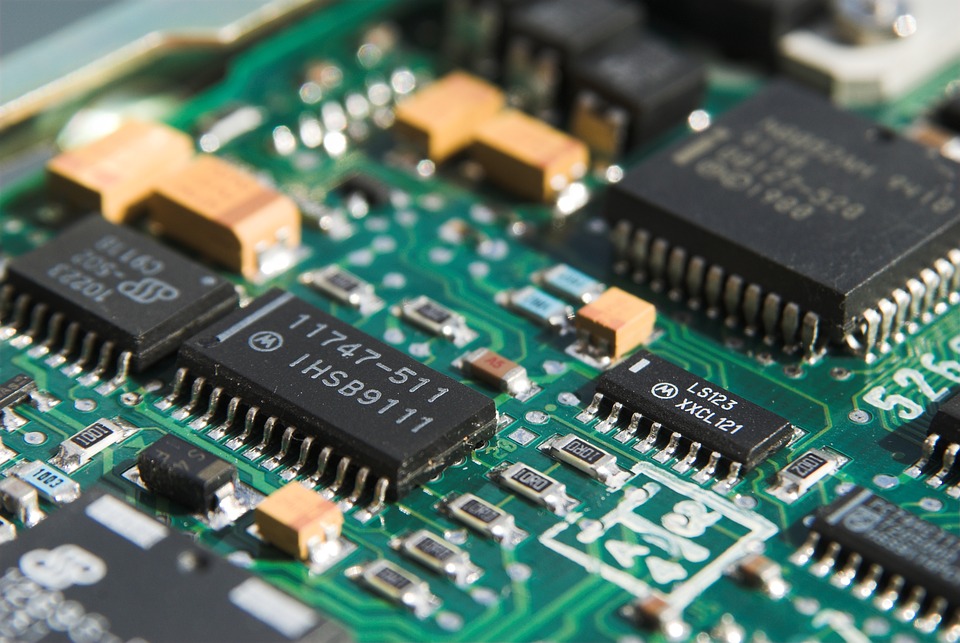

This is the basic and simple inspection performed to test the board. A PCB expert looks at the board with naked eyes or through magnifying glass. The board is compared to the main design document. This method is sufficient for checking obvious flaws like missing components, visible broken or damaged circuits, and other common defaults. The types of defects that can be checked this way depend on the type of board and the types of components used on it. A comprehensive examination can be performed by the inspection staff for thorough checks.

Optical PCB Inspection, A special machine is used to conduct visual inspection of the PCBs. The machine has many light sources and a still or video camera. There can be more than one camera for taking photos or videos. The board is lighted from different angles by the light sources and then the camera takes images or video. The images are compiled to create the full picture of the board. This image is compared with the image of a board that has been set as the standard model. The automatic optical inspection equipment can perform both two and three dimensional inspections. It is an accurate technology that helps detect a wide range of faults in PCBs.

X-Ray Inspection

PCBs have become complex due to the use of surface mount technology. They are quite dense with lots of small components installed in a small space. Only visual inspection is not sufficient to check these boards. They require more advanced inspection methods. An x-ray inspection machine specially designed for PCB inspection helps find faults related to the components, substrate, circuits and traces. This light is capable of passing through less dense object so it can reveal a lot more detail compared to the visual inspection method. It can show even the underside of the solder joints. Problems like bubbles under the solder connections are revealed.

Except for the manual visual inspection, other inspection methods are used on demand. The visual inspection is standard with the PCB making package. More elaborate and complex inspection methods are offered at extra charges. The assembling company can also perform in-circuit testing using latest PCB inspection equipment.